About Us

Gaerte Engines: Building Winners By Building Relationships

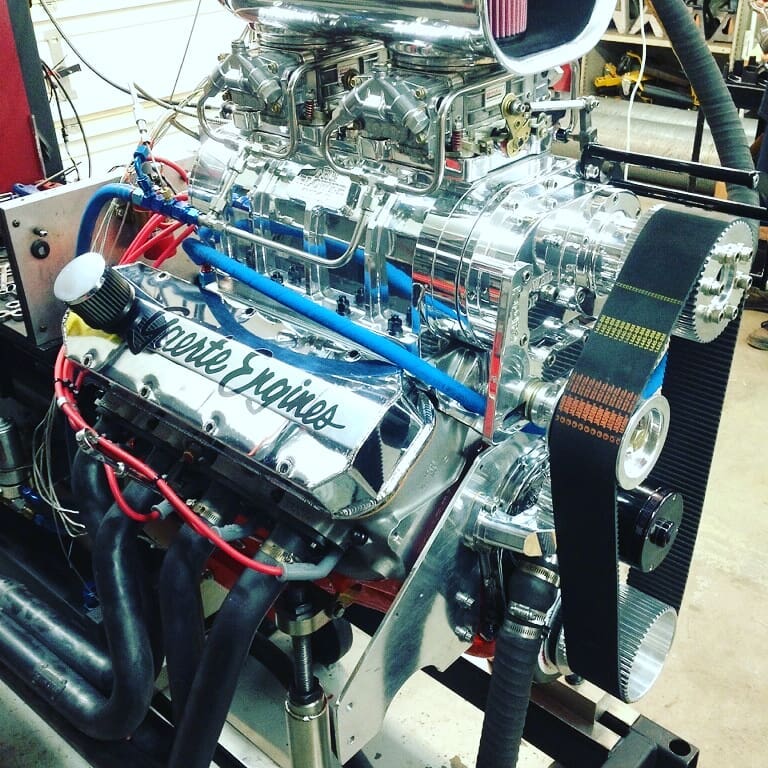

In the summer of 2019 Gaerte Engines was acquired by Steve Rolenc of Tucson AZ and relocated there. Continuing on the the traditions Earl founded the company on, Steve and crew are building the best winning racing engines possible. If you need a Gaerte worked on, send it back and we’ll make it even better than it was!

Providing Expert & Honest Service For Over 20 Years

Our History

Information below is part of the history of Gaerte Engines. Earl’s comments on rebuild cycles* is from several decades ago and in relation to His World of Outlaws engine program at the time. We now go much further between rebuilds these days, without sacrificing any performance or reliability

In the world of sprint cars and midget racing, the name “Gaerte” is recognized as one of the innovators. With a history of building winning motors for such names as Jeff Gordon, Ken Schrader, Ryan Newman, Tony Stewart, Steve Kinser and Sammy Swindell, it’s not surprising that Earl Gaerte and his crew have a reputation for success.

Gaerte has built more than 400 engines a year, primarily for pure race applications. In addition, Gaerte Engines manufactures many of its own parts and modifies and designs many others. From its humble beginnings, the company has exceeded even its owner’s expectations.

In 1969, Gaerte, then parts manager at the local Chevrolet dealer, struck out on his own with $1,000 and some performance parts in the two-car garage behind his house. He began selling the parts to local racers and speed shops and began building engines at the same time. “I built 13 engines the first year,” recalls Gaerte. “They were mostly for drag racers, but I soon saw the writing on the wall – drag racers usually had one motor. If it broke, it sat. Sprint car and circle track racers were addicted to racing – that’s where the volume was.”

Since then, Gaerte’s reputation has been polished by a 10-year association with legendary World of Outlaws racers Sammy Swindell and Steve Kinser. Now, the shop offers popular oval track racing engines for sprint cars (320, 355, 360 and 410 cid alcohol injected), dirt late models (355, 360, 410 and 430 cid carbureted gas or alcohol), four-cylinder midget engines (164-165 cid custom engines based on Gates own design) and USAC Silver Bullet/Silver Crown series aluminum or cast iron alcohol dirt champ engines. “We also dabble in some other things, including marine,” Gaerte explains. “We hold a couple of records in the powerboat associations with our four-cylinders and our 307 V-8.

“We’ve never been very active in street engine building,” Gaerte says. “Occasionally we’ll do a nostalgia motor, but basically it’s all about racing.

Rebuilding: Part of Racing

In some businesses, returned engines could be a sign of poor quality. Earl Gaerte says it’s actually just the opposite.

“A sprint car motor is rebuilt every 6-8 races*. A midget engine will run about 10 races. A late model will last about 1,500 laps before it needs to be rebuilt. That’s part of racing: if you run it hard, it’ll have to be rebuilt.”

When an engine comes in for a rebuild, it is torn down and washed by hand. According to Earl Gaerte, he hasn’t found a machine yet that will wash his blocks clean enough to suit him.

After cleaning, the various components are delivered to the respective department for necessary service. Although different bins of parts may go to the block, head, crank, rod and accessory departments, each part is tagged for identification, so mix-ups don’t happen.

“Everything is tied to the balance number,” says Gaerte. “That’s the key to keeping the parts together. We don’t have any problems there – we’ve given away enough parts over the years we know what we’re doing!”

The tracking procedure includes a detailed check-in sheet which lists each component including serial numbers.

Most service, including machining, welding or repairs, is done in-house, but Gaerte says his days of hand-porting cylinder heads are, for the most part, over. “At one time we had four people sitting here all day grinding heads. Now, we do very little hand porting – it’s all handled with CNC machines.”

Some hand blending is done in the case of head repairs, but in most cases Gaerte says it’s handled automatically. “The quality is so good they don’t need to be ground by hand,” he says.

The CNC head porting and crank grinding are the only services not handled in-house. Three dynos are available to check every engine built

Reputation Isn’t Always Enough

Despite decades of experience and a reputation for excellence, Gaerte says the economy has been tough on his customers, thus, tough on his business.

“If a racer tells you he’s making money racing, he’s lying. All we can do is hope things pull together soon,” says Gaerte.

Gaerte explains that when a leading racing association like World of Outlaws struggles, it makes it difficult for teams to continue. “The guy who’s building middle-level engines will be okay – his customers will still race.”

The engine builder and the racer must be a team, although when faced with trying to turn a profit “it can be a tough deal,” says Gaerte.

This teamwork is part of the reason Gaerte is one of the leading companies developing product for other parts manufacturers as well. “We probably develop more than any other short track racing engine builder. We’re always working on something.”

The latest “something” is a project to develop Mopar blocks and heads for short track racing. “Mopar is pretty receptive to suggestions from engine builders. Some NASCAR technology is carrying over and so we’re helping to develop some things,” Gaerte explains. “It should be pretty big.”

This commitment to excellence in the engine department also carries over to parts. Gaerte builds a number of the parts used in its motors and supplies them to the racing community as well. “We build a lot of the parts people take for granted including front covers for late models, roller tappets, oil pans, oil tanks and valve covers – we do a big business in valve covers.”

Gaerte sells more than 500 dyno-tested carburetors a year, as well as gear drives, camshafts, valve springs and other components. The company is a performance warehouse for many top manufacturers, offering its services to other professional engine builders.

“We’re not looking to attract the mail-order type customer,” explains Gaerte. “We want the relatively low-volume guys who want more than one part at a time. We have two sales people trying to cultivate a relationship with engine builders as well as the parts stores looking for a performance supplier.

The relationships built over the past three decades are evident on every hall and wall at Gaerte Engines. Every kind of performance vehicle imaginable is represented by autographed pictures of some of the top names in racing. Yet this high-profile company has a low-key, small-town atmosphere with an open door policy. Professional racers are encouraged to visit the shop to see their engines being built.

“There’s no black magic here,” says Gaerte. “Any of our customers is welcome to come have a look at how we build his engine.”