Published Articles

By Jim McFarland

ENGINOLOGY published in July 2013 issue of Circle Track

A No-nonsense Engine Builder

ENGINOLOGY GOES 1-ON-1 WITH SRE ENGINE’S STEVE ROLENC

By design, your “Enginology” column was begun to identify and

discuss certain theoretical aspects of engines and engine building.

Over time, it morphed into a combination of technical basics

and their practical applications.

Beginning with this issue of CT, we’re now framing it to include the opinions and practices of notable engine builders who populate the circle track community, some of whom apply theory and others who have gained knowledge through the “school of hard knocks,” so to speak. And, as you might expect, some do both. As always, your comments and suggestions are welcomed.

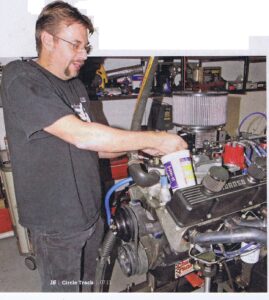

Our first victim, as it were, is Steve Rolenc, the founder and owner of SRE Engine Techniques (www.sre-engines.com), based in Tucson, Arizona.

Our first victim, as it were, is Steve Rolenc, the founder and owner of SRE Engine Techniques (www.sre-engines.com), based in Tucson, Arizona.

Steve Rolenc is a rarity in the engine building business. Can you imagine offering a race engine with a 100-percent, non-conditional, one-year warranty against any failure? He’ll even provide a warranty, if he freshens-up or rebuilds one of his competitor’s engines for a customer. Moreover, he’s been building engines for 25-plus years. We recently caught up with Steve to drill a bit deeper into his philosophies concerning the building of race engines that have been successful both inside and outside the circle track racing community.

What prompted you to get into the engine building

business?

Performance engines and machining have always made sense to me, not unlike how computer programmers understand the language of programming. I believed that my meticulous work combined with particular attention to detail would produce engines of higher power and better quality than the norm. We do it all, not opting to farm out certain engine building steps and processes. That way we can control the end

product. No detail in how we build engines is too small or insignificant.

Let’s talk about your unconditional, one year warranty. What led you to decide this was even doable, given the harshness of the racing engine environment and the fact you cannot control how your engines are treated?

We believe in our engines and how they are built. The fact that we offer a warranty assures our customers will be getting the best parts and building techniques available, based on what we’ve learned over the years. It also guarantees

that we will never compromise quality just to hasten getting engines out the door. For example, our valve jobs require more time to hold concentricity to 0.001-inch, but that makes more power and the engine stays sharp longer. In some extreme cases involving poor valve jobs, guides wear out and valves break because the valve

must flex every time it closes. Our warranty also provides our customers very comprehensive technical support, and we believe this is critical to extending engine life and performance. I know our customers don’t want to deliberately hurt an

engine but we also don’t want them to be timid, worrying about costly damage. Bottom-line, our warranty includes any failure, for any reason that varies from mis-installation, abuse, anybody’s fault (ours or theirs), accidents, fires or parts failures. There’s no arguing about what happened. We stand behind our engines, period.

Well, the next question is how are you able to do this?

The anywer to that goes to some very basic issues. Fundamentally, use only the best parts. Over time, we’ve also learned the best machining and assembly techniques. So we start out by eliminating many of the problems that plague race teams, with respect to their engines. We also provide a considerable amount of technical support, and we believe a big problem causing failures is a lack of this. The warranty also assures constant communication by providing teams with tech support.

Another factor is that we dyno all our engines, using all the customer’s peripheral equipment on our dyno. This includes pumps, filters, bypasses, air cleaners, mufflers (if required), ignition system, and specific fuel. Engine dyno testing needs to be done as scientifically as possible to eliminate variables.

We also provide the proper fuel management algorithms to keep the engine in tune as air density altitude changes and it’s necessary to maintain proper fuel trim. The engine will then make more power, and the chances of failure due to lean fuel enrichment drops to nearly zero.

We’ve found that many teams will give up 10 percent horsepower because of incorrect tuning for fear of leaning out the engine too much. This equates to about 70 hp in an ASCS 360 engine or 90 hp on a 410 motor. How can you beat Outlaw teams if that much power is being forfeited?

We have developed and provide our customers a better and more accurate way to maintain optimum power. All air density data can be plotted on an algorithm for any density encountered. We supply the proper tools, data, and techniques to tune engines to their maximum output so it’s not necessary to waste one or two nights at the track “just getting close” to optimum power. We have nothing to hide and, consequently, provide our customers with a complete build-up sheet, balance printout, head flow, and camshaft profile printouts. After all, these are their engines. That is what you will find different because this is a program, not just a sale. It doesn’t end with a bill and a good-bye. It is not the information that makes our program work. It’s actually the whole package that consists of the best parts, building techniques, scientifically systematic dyno tuning, attention to detail, tech support, fuel management correction factor, honesty, and the desire to work with teams that are as serious about winning as I am.

Let’s shift gears here and look a bit into the future of these type engines. Where do you see EFI fitting into the mix?

I have some thoughts to share on this and hope that I am not alone. From my perspective, there are a lot of carbs out there. EFI does not make racing less expensive and teams, especially in the lower classes, would require computers and training. It also drives the cost associated with the higher classes up and deters teams from stepping up a class.

OK. What are your thoughts about the use of alternative fuels, E85 in particular?

I’m aware that alternative fuels, like E85, have been in the spotlight lately, and I feel teams wanting to move in that direction are trying to lower the cost of racing, not trying to make more power or reliability. This fuel has less BTU content, is less consistent in terms of specific gravity and additive packages since it is bought at local fuel dispensing stations. Some of the racers who have tried it saved money on the fuel, only to be beaten by the higher horsepower potential of methanol. Some even spent more money than they saved by burning down some engines. Of course, the latter could have been avoided by some sensible and careful engine dyno tuning, but that would have taken away from the fuel savings. Plus, if you add the cost of an E85 carburetor, if they had been running gasoline, it is definitely not a cost savings.

Let’s button up this discussion with your views on the crate engine issue and how

this seems to have played into the circle track community.

Let me qualify my thoughts by saying they are based on what I’ve seen in our part of the country (the

Southwest) because I’m not aware of how the crate engine issue has played out elsewhere. But from my perspective, I think the approach is still plagued with problems. These can range from problems associated with getting repairs made to sealed engines to maybe not saving racers as much money as the overall crate program’s intentions have been. Plus, if we’re dealing with sealed engines, it’s possible to purchase the same hardware used to validate that they’ve not been opened when, very possibly, they have been.

Of course, it’s not uncommon in racing when rules changes or options are made available that are intended to save the racer money actually doesn’t work out as planned. But like a lot of other areas in racing that require inspections, it all comes down to how rules or programs are policed.

There a lot of racers who don’t really like the crate engines, they just lack the snorting thunder of a built engine. However, I’ve tried to comment on this question from the perspective of how we’ve seen the crate engine program unfold in our particular area, and I believe the problems pointed out are probably not too different elsewhere.

CircleTrack 1 07.13